What is vinyl flooring?

What is vinyl flooring?

Vinyl flooring refers to the flooring produced with PVC materials. Specifically, it is produced by taking polyvinyl chloride and its copolymer resin as the main raw material, adding fillers, plasticizers, stabilizers, colorants and other auxiliary materials on sheet continuous substrate through coating process or calendering, extrusion or extrusion process

Also known as “light floor material”, it is a very popular new type of light floor decoration material in the world and widely used, such as houses, hospitals, schools, office buildings, factories, public places, supermarkets, businesses, etc.

Other name: PVC flooring, homogeneous & heterogeneous vinyl flooring.

Below, we will explain vinyl flooring in more details from the history, types of vinyl flooring, advantages, differences between other floorings and Longda Flooring products.

It’s an in-depth article that takes 30 minutes to read.

Navigation, click to jump to the section you want to read

Vinyl flooring

1) The history of vinyl flooring

1800s: Rubber flooring was invented. But with production technology limitation and difficulty of getting raw material, people just don’t seem interested in investing time and money in resilient flooring

1845: linoleum was invented, but it was still with slow development.

1890: Rubber locking tiles was invented. With easy installation which can be done by DIY, the resilient flooring was finally becoming more popular.

1926: Vinyl was invented by Waldo Semon, the man who discovered glue while working for BFGoodrich. He had been trying to create a new type of adhesive that would hold up better than what was already on the market at the time and stumbled upon his life-changing find in process. Initially the discovery of vinyl led to its wide use in golf balls and heels for shoes.

1933, Vinyl composition tile (VCT) was invented. The first vinyl flooring was introduced to the public at the Chicago Century of Progress Exposition. The invention of vinyl flooring was a revolutionary moment for both industry and design. This new material would eventually lead to an entirely different way of life as we know it, with its durability ensuring that people could purchase products without worrying about hiding scratches or dirt under their feet all day long, it is widely use

1950: Homogeneous vinyl flooring was invented. This is one single layer homogeneous flooring with same raw material from bottom to top.

1960: Heterogeneous vinyl flooring was invented. This is multi-layer lamination vinyl flooring to meet the market demand. And the coating technology on the flooring surface was first introduced to flooring industry, while widely accepted right away.

1950 – 1980: with the production technology development on the vinyl flooring and more and more people start to like this flooring. It’s Flame resistant, durable and versatile characteristics; make vinyl flooring got into every industry such as schools, hospitals, commercial area, public area. Step by step, it also went from commercial usages to residential usages. This is the most important period for vinyl flooring development, and it is finally becomes a well accepted flooring choice.

Today: vinyl is the second largest selling plastic in the world. With the invention of Luxury vinyl tile (LVT) and Luxury vinyl plank (LVP), and further development of custom print patterns, such as wood look, stone look, stylish design printing; the vinyl flooring can be in a big range of diversity. And the homogenous vinyl flooring technology was reached mature, it is super high durability and low maintaining cost is successfully making homogeneous vinyl flooring the best choice for heavy traffic area such as airport, traffic station, hospital and workshop.

2) Types of vinyl flooring

Heterogeneous & Homogeneous

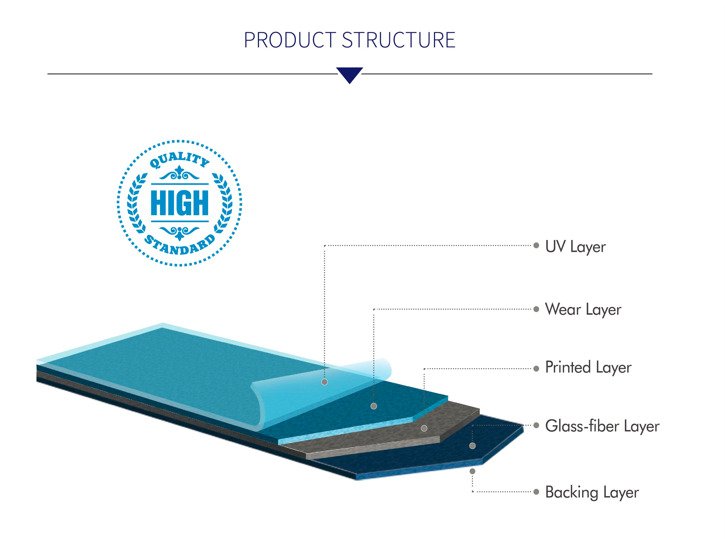

In terms of structure, there are mainly two types: heterogeneous and homogeneous types. Heterogeneous means that it has multi-layer structure, which is generally formed by laminating 4 ~ 5 layers of structure, generally including wear-resistant layer (including UV treatment), printing film layer, glass fiber layer, elastic foaming layer, base layer, etc. Homogeneous means that it is the same design and color from top to bottom.

Vinyl sheet & Vinyl plank/tile

In terms of form, it can be divided into vinyl sheet flooring and vinyl plan/tile flooring. Vinyl Sheet flooring is a roll of floor with relatively soft texture. Generally, its width is 1.5m, 2m, etc., each roll is 20m long, and the total thickness is 1 mm-3.2mm (only for commercial flooring, sports floor can be thicker up to 4mm, 5mm, 6mm, etc.). There are many specifications of vinyl plank and vinyl tile.

The specifications of vinyl plank mainly include:

4″ x 36″ (101.6mm x 914.4mm)

6″ x 36″ (152.4mm x 914.4mm)

8″ x 36″ (203.2mm × 914.4mm),

Thickness: 1.0mm-5.0mm.

The specifications of vinyl tile mainly include:

12″ x 12″(304.8mm x 304.8mm)

18″ x 18″ (457.2mm x 457.2mm)

24″ x 24″ (609.6mm x 609.6mm)

Thickness: 1.0mm-5.0mm.

General type & High durable type

In terms of wear resistance, it is divided into general type and high durable type. General purpose sheet vinyl flooring is mainly produced and used in general places. While some other places with a large flow of people, such as airports and railway stations, need to lay high durable sheet vinyl flooring, which has stronger wear resistance and longer service life

Residential & Commercial

In terms of places of usage, it is divided into residential flooring and commercial flooring.

Residential flooring can be used in living room, bedroom, kitchen, balcony, children room, bathroom, etc

Commercial flooring can be used in below:

Education (including schools, training centers, kindergartens, etc.)

Medical (including hospitals, laboratories, pharmaceutical factories, nursing homes, etc.)

Commercial (including shopping malls, supermarkets, hotels, entertainment and leisure centers, catering industry, specialty stores, etc.)

Sports (stadiums, activity centers, etc.)

Office (office building, conference room, etc.)

Industrial (factory building, warehouse, etc.)

Transportation (airport, railway station, bus station, wharf, etc.)

3) Advantages of vinyl flooring

100% recyclable : Sustainability is the core competence for all the factories right now, when a product is using less raw and 100% recyclable, it is very likely to be the product trend in the future. reinvented vinyl sheet flooring will be available after recycling our vinyl flooring.

Antibacterial and fungicidal : No doubt this is essential for hygienic facility, ceramic tile is used to be the choice for hospital operation room , but this is far from enough, weaponry against bacteria, mold spores that can lead to infection in surgery, this is very important. So the when people talking about hospital grade flooring, normally they mean vinyl sheet flooring.

Fire resistant : think about wood and bamboo flooring when there is a fire and you will know how important it is to have fire resistant function on the floor. With fire resistant flooring, you will no need to worry that the building will be destroyed by flames.

Water proof : This will make the flooring life longer; when the floor is water resistant, meaning that it can handle light moisture without becoming damaged. Mold will still grow on the material if left unchecked for too long but you can added bonus of being able to sweep up any spills or accidents with ease.)

Skid Resistant ( This will make the flooring safer, so you won’t have any worries about it being slippery when walking around.

Light weight : This will help to make the whole building stronger cause this building material is less weight stand on it.

Durable, scratch resistant : This surface treatment will make the flooring life longer. It can withstand heavy traffic without showing any sign of wear and tear, making it the perfect choice for airport and traffic station.

Resilient and comfortable : this is very comfortable for children, olderly, and pet. this resilient flooring will keep you warm in the winter or cool during the summertime.

Easy to install with roll (this can save a lot of money)

Easy to clean and maintain : this is also cost saving, cleaning & maintaining will be very costly for large buildings, so the cost of everyday usage is important.

Custom print available, luxury patterns, stylish designs : you cannot print on wood, natural stone, bamboo, and you need patterns on the floor, then vinyl flooring the best one cause it can be printed, and the printing is very beautiful.

Lower cost: this is cost saving when comparing to wood, bamboo and carpet.

ESD (electrostatic discharge function) : This is a permanent solution that delivers perfect long term results because it is grounded. The safety of people and related equipments are guaranteed.

4) Differences between Vinyl flooring and other floorings

Other flooring types: plastic flooring, SPC & WPC, rubber flooring, linoleum flooring, carpet, ceramic flooring, wooden flooring, bamboo flooring

Vinyl flooring VS Plastic flooring

Plastic flooring (floor leather) is a very low-end product. The main component is plastic, which is afraid of fire, easy to aging and has a short service life.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns and custom print available. It is higher end flooring.

Vinyl flooring: Vinyl sheet/ CVT / LVT / LVP and SPC / WPC

Normally SPC and WPC are also belongs to vinyl flooring. But since it is rigid core, while VCT, LVT, LVP, vinyl sheet are more soft resilient vinyl flooring.

SPC (Stone plastic floor) and WPC ( Wood plastic floor) are rigid flooring. While vinyl flooring is resilient flooring.

SPC & WPC are made of PVC material and marble powder, gypsum powder, active additives, pigments and other materials. The heat generated on the floor by rolling PVC sheet or roll. The floor of PVC floor, such as PVC floor classified as hard quality, is mostly homogeneous and also has composite floor. The homogeneous body of stone plastic floor has poor stain resistance and needs frequent waxing and maintenance. The production cost is low and the floor price is low.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns and custom print available. It is higher end flooring.

Vinyl flooring VS Rubber flooring.

The composition and production process are different: the rubber floor is divided into homogeneous and heterogeneous. Homogeneous rubber floor refers to the floor formed by vulcanization of single-layer or multi-layer structure with consistent color and composition based on natural rubber or synthetic rubber; Heterogeneous rubber floor refers to the floor based on natural rubber or synthetic rubber.

There are differences in design and color: it is difficult to color the rubber floor, because the rubber has strong color absorption, so the color of most rubber floors is relatively single;

The installation difficulty is different: the rubber floor is very heavy and the installation is laborious. Moreover, the installation method of rubber floor is more strict. If the method is wrong, bubbles will appear, and the requirements for self leveling foundation are more perfect. Otherwise, the defects of base course will be exaggerated.

There are differences in market demand and wear strength: rubber flooring is only used in some high-end places due to its high price, and the scope is relatively narrow. In addition, the wear resistance of rubber floor is stronger, which is very suitable for places with large traffic such as airports and stations, as well as aircraft, trains, subways, cars, ships and other means of transportation.

Vinyl flooring is antibacterial, fungicidal, light weight, durable, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns, custom print available and low cost. It is widely used and has great market potential because of its ultra-high cost performance

Vinyl flooring VS Linoleum flooring

Different composition and production process

Linoleum flooring is a mixture of oxidized flaxseed oil, cork and wood powder.

Vinyl flooring is processed with PVC as raw material and filler and other auxiliary materials. From here, linoleum flooring adopts natural raw materials, and vinyl flooring adopts green environmental protection materials.

Different wear resistance and stability

The scratch resistance of linoleum flooring is general, because the linoleum flooring is hard and soft. The dimensional stability of linoleum flooring is general, and strong glue is needed.

Compared with linoleum flooring, vinyl flooring has better wear resistance and high-quality dimensional stability.

Maintenance is difficult and easy

The linoleum flooring needs to be maintained under natural light. The linoleum flooring has poor resistance to maintenance products. Special maintenance products must be used when the linoleum flooring is re polished and waxed. The reason why linoleum flooring is harder than vinyl flooring is that the surface is porous and the stains need to be cleaned quickly, otherwise the surface will leave marks that are difficult to remove, which need to be polished and waxed again.

Vinyl flooring is more convenient to maintain. If the ground is dirty, you only need to wipe it with a rag, and the maintenance times are lower than other floors.

Different installation difficulties

It is troublesome to install the linoleum flooring. If the indoor temperature is too low, the linoleum flooring will break. Because of its unstable size, the product must be installed quickly with strong glue, and the construction is slower than vinyl flooring. Linoleum flooring is not suitable for wet rooms or areas with cleanliness requirements. The linoleum flooring will give off a strong smell and stay in the installed room.

Vinyl flooring is installed quickly. If the ground condition is good, it can be bonded with special environmental protection adhesive and can be used after 24 hours.

Use different

Linoleum flooring is more environmentally friendly and healthy, and is widely used in the field of preschool education.

Vinyl flooring has a wide variety of colors and is used in hospitals, kindergartens, schools, offices and other different fields.

Vinyl flooring VS Carpet

Different composition and production process:

Carpet is a ground paving material made of natural fibers such as cotton, hemp, wool, silk and grass or chemical synthetic fibers through manual or mechanical process.

Differences in performance and maintenance:

Carpets are inflammables, afraid of fire, water and moisture, and maintenance is very troublesome. They are very easy to get dirty, hide dirt and breed bacteria.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns, custom print available and low cost.

Vinyl flooring VS Ceramic flooring

Different composition and production process:

Ceramic tile is a kind of acid-base resistant porcelain or stone building or decoration material formed by grinding, mixing, pressing, glazing and sintering of refractory metal oxide and semi metal oxide, which is generally called ceramic tile. Its raw materials are mostly mixed with clay, quartz sand and so on.

Differences in performance and maintenance:

The ceramic tile is not slip resistant and the texture is cold. It is also troublesome to maintain and is very easy to get dirty.

Difference in installation:

The ceramic tile is very heavy, the installation is laborious, and it is difficult to remove after installation, so it cannot be reused.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns, custom print available and low cost.

Vinyl flooring VS Wood flooring

Wood flooring can be roughly divided into three categories: solid wood flooring, solid wood composite flooring and laminate flooring.

Solid wood floor is a natural material, which has the irreplaceable advantages of synthetic materials, non-toxic and tasteless, comfortable foot feeling, warm in winter and cool in summer. However, it also has some disadvantages, such as high price, large consumption of hardwood resources, large workload of laying and installation, difficult maintenance (fear of fire, water and moisture) and large size change in the width direction of the floor with the change of relative humidity.

The appearance of solid wood composite floor has the same beautiful wood texture as solid wood floor, good dimensional stability and easy to lay and maintain. However, it is still unable to get rid of the shortcomings of fear of fire, water and moisture. It is not as environmentally friendly and wear-resistant as PVC floor.

The base material of laminate floor is medium density or high-density fiberboard and particleboard, with good dimensional stability. The surface layer is impregnated decorative paper containing wear-resistant materials, which ensures the wear resistance of the surface layer, good cigarette burning resistance, scratch resistance and pollution resistance. Compared with the first two, there is still a considerable gap compared with the super wear resistance and pollution resistance of PVC floor.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns, custom print available and low cost.

Vinyl Flooring VS Bamboo flooring

Bamboo flooring is also made of natural bamboo and wood, which is green and environment-friendly. However, bamboo flooring is also afraid of water, fire and moisture. It is sensitive to indoor temperature and humidity, easy to expand, deform or dry shrink and crack, and even moldy in serious cases.

The surface of bamboo floor is painted, with poor wear resistance and scratch resistance.

The maintenance of bamboo floor is troublesome and needs frequent waxing maintenance. In addition, it has poor corrosion resistance.

Vinyl flooring is antibacterial, fungicidal, fire resistant, water proof, skid resistant, light weight, durable, scratch resistant, resilient, comfortable, each to install, easy to clean, easy to maintain, with luxury patterns, custom print available and low cost.

5) Introduction of Longda Vinyl flooring.

Longda Flooring is the leading vinyl sheet flooring manufacturer from China. We have more than 300+ stylish patterns and increasing every month.

The annual capacity in our factory is 36 million m² . ( # 1 in China) And our 6 million m² daily stock can support next day shipping.

We have 4 main products:

This article is written by Longda Flooring (www.longdaflooring.com), the largest vinyl sheet flooring manufacturer from China.

Please contact Longda flooring for a free quote on your vinyl flooring needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longda flooring

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086-138 2882 1440

- Fax: 86-312-5863390

- Email: sales@longdaflooring.com

Follow us

Copy right by Longda China