What is heterogeneous vinyl sheet flooring?

What is heterogeneous vinyl sheet flooring?

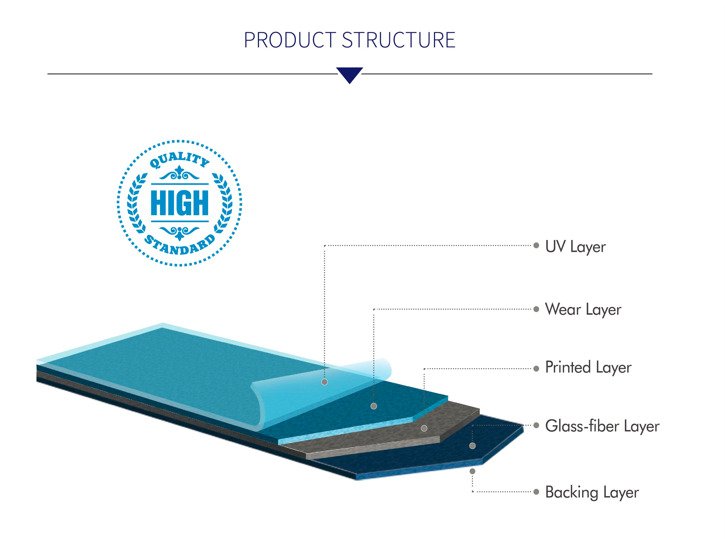

Heterogeneous vinyl sheet flooring is the multi layer flooring with different contents from top to bottom. It combines with UV layer, Wear layer, Printed layer, Glass-fiber layer and Backing layer. It can be custom printed with all kinds of stylish patterns and innovation designs. With the advantage of cushioning, comfort, waterproof, durability and affordability, it is the perfect choice for public areas need luxury vinyl sheet such as: school, mall, office, GYM and workshop.

Below, we will explain heterogeneous vinyl sheet in more details from the history, production process, advantages, applications and Longda factory products.

It’s an in-depth article that takes 20 minutes to read.

Navigation, click to jump to the section you want to read

1) The history of heterogeneous vinyl sheet flooring

1800s: Rubber flooring was invented. But with production technology limitation and difficulty of getting raw material, people just don’t seem interested in investing time and money in resilient flooring

1845: linoleum was invented, but it was still with slow development.

1890: Rubber locking tiles was invented. With easy installation which can be done by DIY, the resilient flooring was finally becoming more popular.

1926: Vinyl was invented by Waldo Semon, the man who discovered glue while working for BFGoodrich. He had been trying to create a new type of adhesive that would hold up better than what was already on the market at the time and stumbled upon his life-changing find in process. Initially the discovery of vinyl led to its wide use in golf balls and heels for shoes.

1933, Vinyl composition tile (VCT) was invented. The first vinyl flooring was introduced to the public at the Chicago Century of Progress Exposition. The invention of vinyl flooring was a revolutionary moment for both industry and design. This new material would eventually lead to an entirely different way of life as we know it, with its durability ensuring that people could purchase products without worrying about hiding scratches or dirt under their feet all day long, it is widely use

1950: Homogeneous vinyl flooring was invented. This is one single layer homogeneous flooring with same raw material from bottom to top.

1960: Heterogeneous vinyl flooring was invented. This is multi-layer lamination vinyl flooring to meet the market demand. And the coating technology on the flooring surface was first introduced to flooring industry, while widely accepted right away.

1950 – 1980: with the production technology development on the vinyl flooring and more and more people start to like this flooring. It’s Flame resistant, durable and versatile characteristics; make vinyl flooring got into every industry such as schools, hospitals, commercial area, public area. Step by step, it also went from commercial usages to residential usages. This is the most important period for vinyl flooring development, and it is finally becomes a well accepted flooring choice.

Today: vinyl is the second largest selling plastic in the world. With the invention of Luxury vinyl tile (LVT) and Luxury vinyl plank (LVP), and further development of custom print patterns, such as wood look, stone look, stylish design printing; the vinyl flooring can be in a big range of diversity. And the homogenous vinyl flooring technology was reached mature, it is super high durability and low maintaining cost is successfully making homogeneous vinyl flooring the best choice for heavy traffic area such as airport, traffic station, hospital and workshop.

Heterogeneous vinyl sheet flooring

2) Heterogeneous sheet vinyl production process.

Step 1: Mixing: PVC powder, plasticizer, stabilizer, lubricant, filler and other raw materials shall be fed and mixed in a certain order

Step 2: Internal mixing: put the mixture into the internal mixer for internal mixing

Step 3: Open refining: calendered into semi-finished products, middle layer and bottom layer

Step 4: Cutting of fabrics and transparent materials: cut the transparent wear-resistant layer and printing decorative layer required in the production process according to the product size

Step 5: printing

Step 6: Mold laying: according to the product structure, formula and customer’s design and color requirements, lay and place in a standardized manner and overlap neatly

Step 7: Oil pressure: after hot pressing, the product layers are firmly bonded together

Step 8: UV finishing

Step 9: Tempering: the product is unstable after hot pressing, and the physical properties of the product will become stable after fire heat treatment

Step 10: Aging: Put the flooring in Constant temperature room until it is normal temperature.

Step 11: Cutting: Cut into needed size.

Step 12: Inspection

Step 13: Packing

3) Advantages of heterogeneous vinyl sheet flooring.

100% recyclable ( Sustainability is the core competence for all the factories right now, when a product is using less raw and 100% recyclable, it is very likely to be the product trend in the future. reinvented vinyl sheet flooring will be available after recycling our vinyl flooring)

Antibacterial and fungicidal ( No doubt this is essential for hygienic facility, ceramic tile is used to be the choice for hospital operation room , but this is far from enough, weaponry against bacteria, mold spores that can lead to infection in surgery, this is very important. So sheet vinyl flooring is the hospital grade flooring)

Fire resistant (think about wood and bamboo flooring when there is a fire and you will know how important it is to have fire resistant function on the floor. With fire resistant flooring, you will no need to worry that the building will be destroyed by flames)

Water proof ( This will make the flooring life longer; when the floor is water resistant, meaning that it can handle light moisture without becoming damaged. Mold will still grow on the material if left unchecked for too long but you can added bonus of being able to sweep up any spills or accidents with ease.))

Skid Resistant ( This will make the flooring safer, so you won’t have any worries about it being slippery when walking around.)

Light weight ( This will help to make the whole building stronger cause this building material is less weight stand on it.)

Durable, scratch resistant ( This surface treatment will make the flooring life longer. It can withstand heavy traffic without showing any sign of wear and tear, making it the perfect choice for airport and traffic station.)

Resilient and comfortable ( this is very comfortable for children, olderly, and pet. this resilient flooring will keep you warm in the winter or cool during the summertime.)

Easy to install with roll (this can save a lot of money)

Easy to clean and maintain ( this is also cost saving, cleaning & maintaining will be very costly for large buildings, so the cost of everyday usage is important)

Custom print available, luxury patterns, stylish designs ( you cannot print on wood, natural stone, bamboo, and you need patterns on the floor, then vinyl flooring the best one cause it can be printed, and the printing is very beautiful.)

Lower cost. ( this is cost saving when comparing to wood, bamboo and carpet.)

4) Applications:

- Hospital

- Airport

- School

- Library

- Exhibition centre

- Shopping mall

- Office

- Workshop

- GYM

5) Introduction of Longda heterogeneous vinyl sheet flooring product.

Started from 2003, our factory have been successfully provided more than 150 million m² sheet vinyl flooring to both commercial and residential customers.

Today we have total 2 heterogeneous sheet vinyl production lines with total annual capacity of 22 million m2, and we are now the leading heterogeneous vinyl flooring manufacturer in China.

We have 11 series of these heterogeneous flooring, total more than 200 patterns so far; and still increasingly each month. We are leading the market trend in the stylish design.

This article is written by Longda Flooring (www.longdaflooring.com), the largest vinyl sheet flooring manufacturer from China.

Please contact Longda flooring for a free quote on your vinyl flooring needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longda flooring

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086-138 2882 1440

- Fax: 86-312-5863390

- Email: sales@longdaflooring.com

Follow us

Copy right by Longda China