Ultimate Guide: How to Hot Weld Commercial Vinyl Sheet Flooring

After the installation of commercial vinyl sheet flooring, it is generally necessary to weld the joints. By welding robs, it is possible to effectively prevent water from entering the bottom layer during daily use, which can affect the firmness of the adhesive. At the same time, it can also prevent bacteria from growing at the joints and improve the service life of the floor, among other benefits. There are three basic processes for plastic floor welding lines: slotting, hot welding, and flattening of welding seams.

1. Slotting

Slotting is the process of slotting at the joints of the floor, which ensures that the edges of the floor are clean and that the welding rod can tightly bond with the ground material and weld firmly. When slotting, use a U-shaped cutting tool for slotting, and electric or manual slotting tools can also be used. After slotting, it is necessary to keep the groove clean and free of debris. Slotting should be done symmetrically on both sides of the coil, not just on one side. The groove should not be bottomed out, and the depth of the groove depends on the thickness and type of welding material, as well as the diameter of the special welding rod. Slot requirements: Note that the depth of the slot must not exceed 1/2 of the diameter of the special welding rod, nor should it exceed 2/3 of the thickness of the ground material.

The two welded PVC floors are not firmly attached and the bonding surface is small, which naturally affects the bonding strength.

2. Welding

Before hot welding the rob, residual dust and debris must be removed from the groove.

The temperature of hot welding must be adjusted according to the type of ground material and specialized welding rod used.

Temperature judgment standard: It can effectively dissolve the welding rod, but will not overheat or scorch the welding rod or PVC coil.

The temperature of the welding gun is about 350 degrees, and the temperature of the welding machine varies.

The temperature and speed of hot welding must be adjusted according to the actual situation. Pay attention to the reaction of the welding rod, as the welding temperature, speed, and force used have a direct impact on the effectiveness of hot welding.

The temperature and movement speed of the welding gun should be matched to stick the welding rob. If the welding wire dissolves too quickly, it will not stick firmly. If the welding rob is too slow, it may burn.

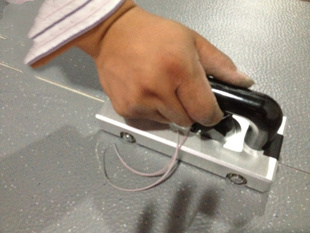

3. Flatten the welding seam

After the welding rod has completely cooled down, use a welding rod flattener or crescent shaped cutter to remove the remaining protrusions. When cutting, pay attention to uniform cutting speed to increase the aesthetics of the welding rod after cutting.