The Difference Between Vinyl Sheet, LVT, LVP, SPC and WPC

What is vinyl flooring?

Vinyl flooring refers to the flooring produced with PVC materials. Specifically, it is produced by taking polyvinyl chloride and its copolymer resin as the main raw material, adding fillers, plasticizers, stabilizers, colorants and other auxiliary materials on sheet continuous substrate through coating process or calendering, extrusion or extrusion process

Also known as “light floor material”, it is a very popular new type of light floor decoration material in the world and widely used, such as houses, hospitals, schools, office buildings, factories, public places, supermarkets, businesses, etc.

There are five common types of vinyl flooring

Vinyl sheet

LVT: Luxury vinyl tile

LVP: Luxury vinyl plank

WPC: Wood plastic composite or RVP(rigid vinyl plank)

SPC: Stone plastic composite or RVP(rigid vinyl plank)

Note: In this article we will named vinyl sheet, LVT and LVP as vinyl flooring as what the market usually do. While WPC for WPC, SPC for SPC.

Today we will talk about the difference between Vinyl Flooring (vinyl sheet, LVT, LVP), SPC and WPC.

It’s an in-depth article that takes 30 minutes to read.

Navigation, click to jump to the section you want to read

Difference between Vinyl Flooring (vinyl sheet, LVT, LVP), SPC and WPC

1) General summary: 4 ways of categories

In terms of structure, there are mainly two types: heterogeneous and homogeneous.

Heterogeneous vinyl flooring is the multi layer flooring with different contents from top bottom. It combines with UV layer, Wear layer, Printed layer, Glass-fiber layer, foamed layer and Backing layer. It can be custom printed with all kinds of stylish patterns and innovation designs.

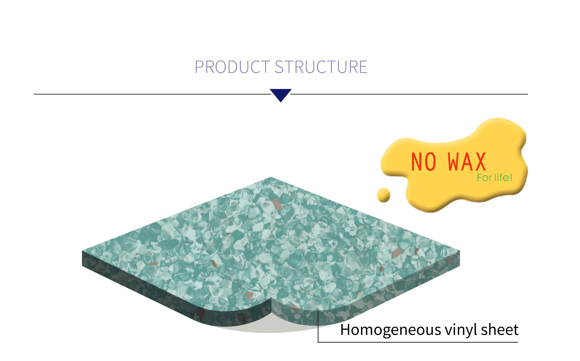

Homogeneous vinyl flooring is the one single layer flooring with same content from top to bottom made by same mixed raw materials.

Normally Vinyl sheet can be with both homogeneous and heterogeneous, while LVP & LVT are heterogeneous. SPC and WPC can also call heterogeneous.

In terms of size: it can be divided into sheet vinyl, vinyl plank(LVP) and vinyl tile(LVT) flooring. SPC and WPC are also can be call as plank.

In terms of hardness, it can be divided into semi-rigid and rigid. Vinyl sheet, LVT and LVP are semi-rigid, while WPC & SPC are rigid core flooring.

In terms of installation, it can be divided into Click locking, Dry back and Loose lay.

Click locking means one piece of flooring will lock into another piece of flooring so all the flooring will connect together. SPC, WPC can be with click locking.

Dry back needs hydrated glue and other auxiliary materials, also known as glue down. Vinyl sheet, LVT, LVP will be with dry back.

Loose lay can be directly paved (there is a layer of black skin on the bottom material of loose lay, which can’t be pushed on the plane.) LVT, LVP will be with loose lay.

2) Vinyl flooring ( vinyl sheet, LVT and LVP)

Advantages and disadvantages of vinyl flooring (vinyl sheet, LVT and LVP)

Six advantages:

1, Green environmental protection

The main raw material for the production of vinyl flooring is polyvinyl chloride. Polyvinyl chloride is an environmentally friendly and non-toxic renewable resource. It has been widely used in people’s daily life, such as tableware and medical infusion pipe bags. Its environmental protection does not need to be worried.

2, Excellent wear resistance

There is a special PVC wear-resistant layer on the surface of vinyl flooring, and its wear-resistant revolution can reach 300000 revolutions. According to the different wear-resistant thickness, it can be used for 5-10 years under normal conditions. The thickness and quality of the wear-resistant layer directly determine the service time of vinyl flooring. The standard test results show that the 0.55mm thick wear-resistant layer ground can be used for more than 5 years under normal conditions, and the 0.7mm thick wear-resistant layer ground is enough to be used for 10 years Above, so it is super wear-resistant. Because it has super wear-resistant, PVC flooring is becoming more and more popular in hospitals, schools, office buildings, shopping malls, supermarkets, vehicles and other places with large traffic. (for the wear-resistant of wear-resistant layer, at present, it is mainly measured by loss, that is, quality reduction)

3, Resilient

Vinyl has soft texture, so it has good elasticity. It has good elastic recovery under the impact of heavy objects. At the same time, vinyl flooring has strong impact resistance and strong elastic recovery for the impact damage of heavy objects without damage. Excellent vinyl flooring can minimize the damage to human body and disperse the impact on feet. The latest research data show that in people After the space with large flow is paved with excellent vinyl flooring, the rate of personnel falling and injury is reduced by nearly 70% compared with other floors.

4, Fire resistant

The fire prevention index of qualified vinyl flooring can reach grade B1, which means that the fire prevention performance is very excellent, second only to stone. It is extinguished when it is away from the fire.

5, Convenient maintenance

The maintenance of vinyl flooring is very convenient. If the floor is dirty, wipe it with a mop. If you want to maintain the lasting and bright effect of the flooring, you only need to wax and maintain it regularly, and the maintenance times are far lower than that of laminate floor

6, Waterproof and moisture-proof

Because the main component of vinyl flooring is vinyl resin and has no affinity with water, it is naturally not afraid of water. As long as it is not soaked for a long time, it will not be damaged; and it will not mildew due to high humidity.

Two disadvantages:

Non natural materials and high requirements for base floor (when LVT floor is laid, the base must be flat, solid and dry, and the surface of plastic floor shall be smooth, the internal and external corners shall be square, free of edges, oil, dust and impurities).

3) WPC (wood plastic composite)

WPC combines the waterproof and stability of vinyl flooring and is as easy to install as laminate wood flooring.

With the increase of cork and EVA pad, the foot feel and sound insulation effect will be better than the latch floor of vinyl flooring.

WPC uses all environmentally friendly materials, which will be more environmentally friendly than laminate wood flooring.

In short: WPC has the advantages of vinyl flooring and laminate wood flooring.

Composition

WPC: Wood Plastic Composition= vinyl flooring Layer + WPC Core

WPC vinyl flooring layer and WPC layer are bonded by glue, and the peel strength is very good, even better than that of vinyl flooring color film layer and frosted sheet after hot pressing

WPC is more stable than vinyl flooring:

The WPC floor shall be kept under the high temperature of 80 ° C plus or minus 2 ° C for 6 hours, and then put out at the normal temperature of 23 ° C plus or minus 2 ° C and 50% humidity for 24 hours. The following conclusions are drawn:

The shrinkage of the length is 0.08%

The shrinkage of width is 0.05%

Warpage: 0.25mm

LVP: 0.08-0.15%

Warpage: 0.5-1.2mm

WPC advantages

WPC engineered vinyl flooring – WPC’s price is gold. WPC’s price of 5.5mm is basically the same price level as vinyl’s 5.0mm latch and glue free products, but higher than magic buckle, and far higher than water washing glue and ordinary vinyl flooring (glue brushing type);

The installation cost of WPC is far lower than that of ordinary rubber brushed vinyl flooring, lower than that of ordinary PVC latch floor, and there is little difference between the installation cost of glue free vinyl flooring, magic buckle and water washed rubber vinyl flooring;

WPC’s waterproof property is quite good, and the waterproof property of wood plastic layer is also very stable. On the contrary, the waterproof effect of magic buckle, water washing glue and ordinary rubber brushing vinyl flooring is general because it involves glue;

The installation convenience of WPC is relatively convenient due to the angle tap installation method, which is suitable for DIY. Of course, dry back, which needs to be paid separately, is the worst at this point.

WPC flooring is certainly good in terms of mute and foot feeling, especially WPC floor with cork or EVA pad;

WPC is also very good in environmental protection, including formaldehyde emission, heavy metals, especially reach test. All 144 items passed.

WPC has good sound absorption effect and good energy saving, which makes the indoor energy saving up to more than 30%.

WPC has the advantages of simple installation, convenient construction, no complicated construction process, and saves installation time and cost

WPC flooring is a weak point in terms of recyclability after use, because WPC (wood plastic) can not be recycled and reused. vinyl flooring of other products can be recycled as recycled materials.

Several problems needing attention in WPC’s communication with customers

(1) Because the vinyl flooring layer of WPC is generally only 1.5mm thick, the plate pattern shall be relatively flat as far as possible. Do not grasp it with hands and classic slate (slate pattern). The rate of defective products will be very high.

(2) The cost of 6.0mm wood plastic layer is 1.80 US dollars per square meter higher than that of 5.0mm wood plastic layer

WPC + 2.0mm EVA form: price + usd1.00sqm

WPC + 1.5mm cork: price + usd1.50sqm

4) SPC (Stone plastic composite)

Stone plastic composite (SPC) It is a new type of environment-friendly floor developed based on high technology. It has the characteristics of zero formaldehyde, mildew proof, moisture-proof, fire-proof, insect proof and simple installation. SPC floor is a product of extruding PVC substrate by extruder combined with T-shaped die, and heating and laminating PVC wear-resistant layer, PVC color film and PVC substrate by three roll or four roll calender at one time. The process is simple and the lamination is completed by heat, No glue is required. SPC flooring materials use environmentally friendly formula and do not contain heavy metals, phthalates, methanol and other harmful substances. They are widely popular in developed countries in Europe and the United States and the Asia Pacific market. With their excellent stability and durability, stone plastic flooring not only solves the problem of damp and mildew of solid wood flooring, but also solves the problem of formaldehyde of other decoration materials. It can be used as a color map for selection Many cases, suitable for indoor home decoration, hotels, hospitals, shopping malls and other public places.

Shrinkage of SPC floor: ≤ 1 ‰ (after tempering), ≤ 2.5 ‰ (before tempering), (shrinkage test standard: 80 ℃, 6 hours);

SPC floor density: 1.9 ~ 2T / m3;

Advantages of SPC floor: the physical indexes of SPC floor are stable and reliable, and the chemical indexes meet international and national standards;

Disadvantages of SPC floor: SPC floor has high density, heavy weight and high transportation cost;

Compared with vinyl flooring and WPC flooring, SPC flooring has simple processing and manufacturing process.

Advantages of SPC environmentally friendly flooring:

SPC floor is a new type of environment-friendly composite material product. Its advantages are as follows:

(1) Waterproof and moisture-proof. It fundamentally solves the problem that wood products are easy to rot, expand and deform after absorbing water in humid and watery environment, and can be used in the environment where traditional wood products cannot be used;

(2) Insect and termite prevention, effectively eliminate insect harassment and prolong service life;

(3) It is colorful and has many colors to choose from. It not only has natural wood feeling and wood texture, but also can customize the required colors according to its own personality;

(4) Strong plasticity, can easily realize personalized modeling and fully reflect personalized style;

(5) High environmental protection, pollution-free, pollution-free and recyclable. The product does not contain benzene and formaldehyde. It is an environmental protection product and can be recycled, which greatly saves the use of wood, is suitable for the national policy of sustainable development and benefits the society;

(6) High fire resistance. It can be effectively flame retardant. The fire rating reaches grade B1. It will extinguish itself in case of fire and will not produce any toxic gas;

(7) Good machinability, can be ordered, planed, sawn, drilled, and the surface can be painted.

This article is written by Longda Flooring (www.longdaflooring.com), a leading vinyl sheet flooring manufacturer from China.

Please contact Longda flooring for a free quote on your vinyl flooring needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longda flooring

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086-138 2882 1440

- Fax: 86-312-5863390

- Email: sales@longdaflooring.com

Follow us

Copy right by Longda China