Everything You Need to Know About ESD Flooring

What is ESD Flooring

ESD flooring is the flooring that prevent a build-up of static electrical charges in the human body by dissipates charges on the ground. This is a permanent solution that delivers perfect long term results because it is grounded. The safety of people and related equipments are guaranteed.

As a person walks across flooring, it is very easy to build up static charge through friction because the environment acts as an insulative material. This can cause mayhem in certain industries.

In order to save lives and protect electronic equipments, more and more places are choosing ESD flooring.

In this article, we will talk about everything you need to know about ESD flooring.

It’s an in-depth article that takes 45 minutes to read.

Navigation, click to jump to the section you want to read

ESD Flooring

1) Detail explanation of ESD flooring

ESD flooring, can be divided into static dissipative flooring 106Ω to 109Ω(1 Mohm to 1000 Mohms) and conductive flooring 2.5×104Ω to 106Ω(.025 Mohms to 1 Mohms), provide superior static control, inhibiting static electricity on a person or from reaching sensitive equipment.

Static conductive flooring grade:

In high-precision rooms, such as wafer production lines, operation rooms, ammunition depots and other places where static electricity cannot gather, static electricity must be discharged through static conductive flooring materials to avoid danger.

For example, during surgery, doctors need to monitor the indexes of various precision instruments. If the readings of computers and instruments are incorrect due to electrostatic interference, doctors may misjudge and cause danger to patients.

For another example, electrostatic accumulation may cause sparks. If it occurs in an ammunition depot, it may cause explosion and disaster.

static dissipative flooring grade:

Office, school, library, museum, hospital, ward, nursing center, indoor of various public places, factory office, manufacturing and processing plant are ok to use static dissipative flooring.

2) Benefits of ESD flooring

Protecting personnel from injury or loss of life due to shock or explosion. ESD flooring is often used to protect those working in cleanrooms.

Protecting sensitive electronic components from damaging static electricity, often in computer and electronics manufacturing

Saving money on replacing or repairing electronic equipment that has failed or been damaged due to static electricity

Creating a 100% effective static-controlled environment, complete with ESD footwear

3) Basic Technical indicators.

- Conductivity: 2.5×104Ω to 109Ω

- Pyrotechnic resistance: not less than 1600 ℃

- Wear resistance: T, P

- Extreme cold and heat resistance: 15 ℃ – 105 ℃

- After 10 quench and heat cycles, no obvious cracks appear

- Breaking modulus: The minimum value shall not be less than 27mpa

- Warpage: ± 0.5%

4) Key points of design

- The ESD raised flooring shall reach the fire rating

- The height of ESD raised flooring shall be determined according to the use requirements.

For wiring only: the basic size is 250mm.

For wiring and air conditioning air warehouse: the basic size is 500mm. The detachable plates of the flooring can be interchanged and have high manufacturing accuracy, so as to ensure the tightness required when the floor space is used as an air-conditioning air warehouse.

- The paving construction of raised flooring in ESD machine room is the last stage of building decoration. The flooring shall be cleaned and the raised flooring shall be paved after the laying of indoor ceiling board and the installation of ceiling lamps and vents.

- The raised flooring of the ESD machine room is laid on the leveled cement mortar cushion. In order to reduce the height of the ground practice, when it is directly laid on the structural flooring slab, the surface of the structural flooring slab shall be flat, and the interface agent shall be sprayed to solidify the concrete surface so that the ground will not sand.

- The flooring surface shall be non slippery, wear-resistant and pollution resistant.

- After the flooring is installed, it must be grounded; otherwise it will not play an ESD role.

5) Applications for ESD Flooring

Computer rooms

Data center and network office

Electronic labs

Electronics manufacturing

Cleanroom

Hyperbaric spaces in healthcare settings, hospital

Telecommunication center

Aerospace and defense

Automotive and transportation

Explosives and munitions

Medical manufacturing

6) ESD Flooring Category

Direct installation flooring

ESD direct installation flooring is generally divided into ESD ceramic tile, ESD rubber flooring, ESD vinyl flooring and ESD epoxy flooring

- ESD ceramic tile

During the production process of ceramic tiles, ESD functional powder is added for physical modification, so the ESD performance is very stable, the resistance value is between 106Ω to 109Ω

Laying copper strip under the flooring can better enhance the conductivity.

- ESD vinyl flooring

ESD vinyl sheet and ESD vinyl tile are directly paved, with fast installation speed (but professional installers are required for installation, otherwise there will be arching and blistering). The electronic static discharge control performance is relatively stable. ESD vinyl flooring is the best ESD flooring.

- ESD epoxy flooring

Excellent antistatic effect, lasting, not affected by time, temperature, humidity, etc;

It is made of solvent-free high-grade epoxy resin and high-quality curing agent;

The surface is smooth, beautiful, moisture-proof and mirror effect;

It has good corrosion resistance to acid, alkali, salt and oil media, especially strong alkali;

Wear resistance, pressure resistance, impact resistance and certain elasticity

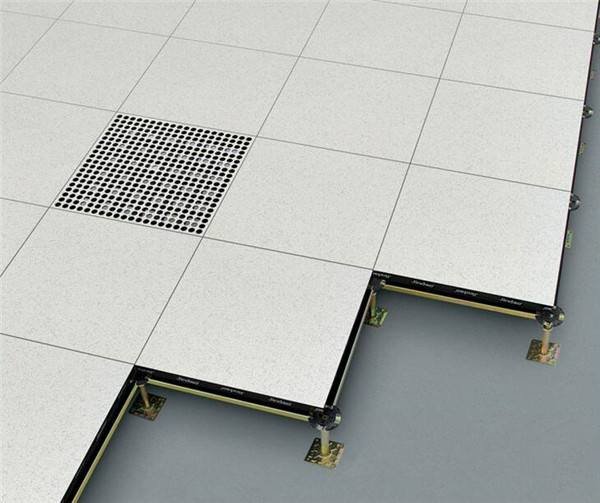

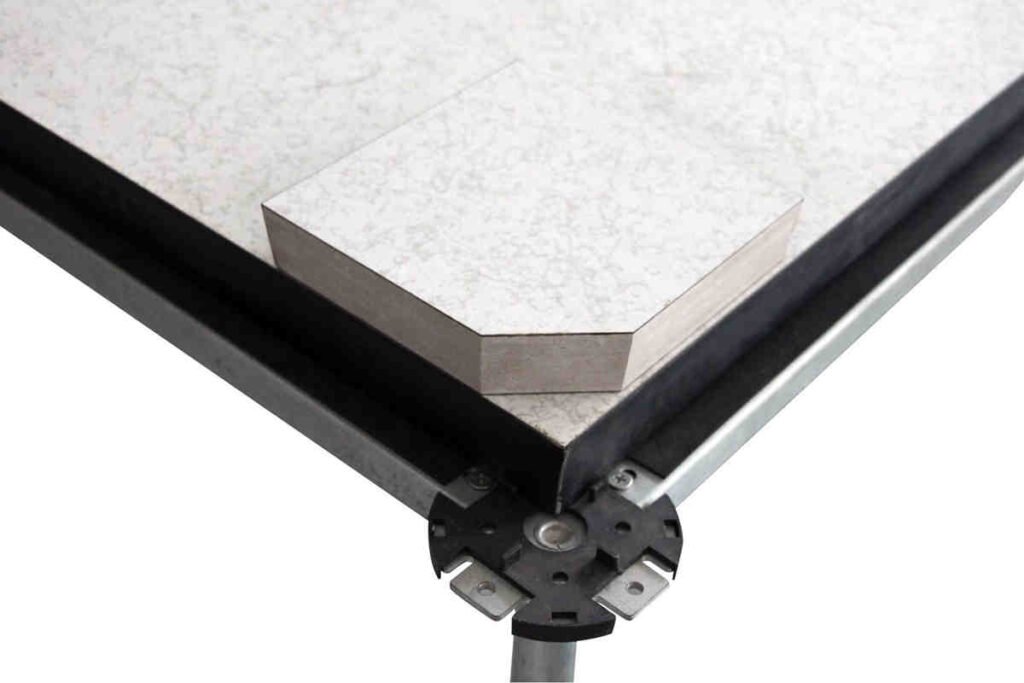

Raised flooring

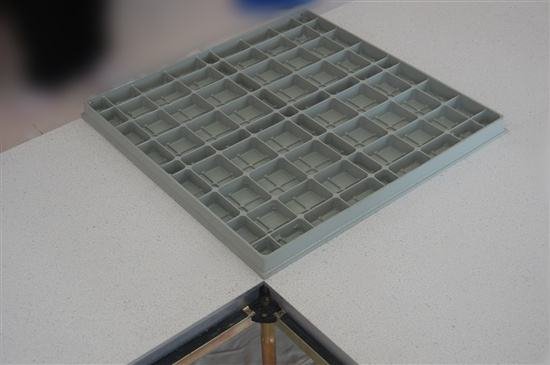

ESD raised flooring is generally divided according to different base materials and veneer materials. The base materials include steel base, aluminum base, composite base, particleboard base (wood base), calcium sulfate base, etc. The facing materials include ESD ceramic tiles, melamine (HPL), PVC, etc. In addition, there are ESD plastic floors, OA network floors, etc. The following is a brief introduction to several types of floors commonly used in the market.

- Ceramic ESD flooring

The ESD ceramic tile is used as the surface layer, the composite all steel flooring or cement particleboard, and the surrounding conductive adhesive strip is processed (the ceramic flooring without adhesive strip is easy to fall off when bumping). It has the advantages of stable ESD performance, environmental protection, fire prevention, high wear resistance, high service life (service life of more than 30 years), high bearing capacity (uniform load of more than 1200kg / m2), waterproof, moisture-proof and good decoration effect. It is suitable for all kinds of machine rooms. The disadvantage is that the flooring itself is heavy (more than 15kg for a floor), which has a certain impact on the bearing capacity of the floor; In addition, professional installation workers are also required to install it, otherwise the installation will be uneven.

- All steel ESD flooring

High wear-resistant melamine HPL fireproof board or vinyl is used as the surface layer and the base material of steel shell structure. In addition, there are borderless and borderless according to whether there is black adhesive strip.

The advantages of all steel flooring are convenient construction, no gap problem after installation, and convenient replacement. The disadvantages are that the surface material is not wear-resistant, short service life, easy peeling and warping, and it will be replaced in a few years.

- Aluminum alloy ESD flooring

The product adopts high-quality cast aluminum profile, which is stretched and formed. The surface layer is made of high wear-resistant vinyl or HPL veneer and pasted with conductive adhesive. It has the effect that the base material will not rust permanently and can be used for many times, so as to effectively solve the product defects of composite flooring and all steel flooring. However, the high-grade custom made ESD flooring is too expensive.

7) Installation requirements

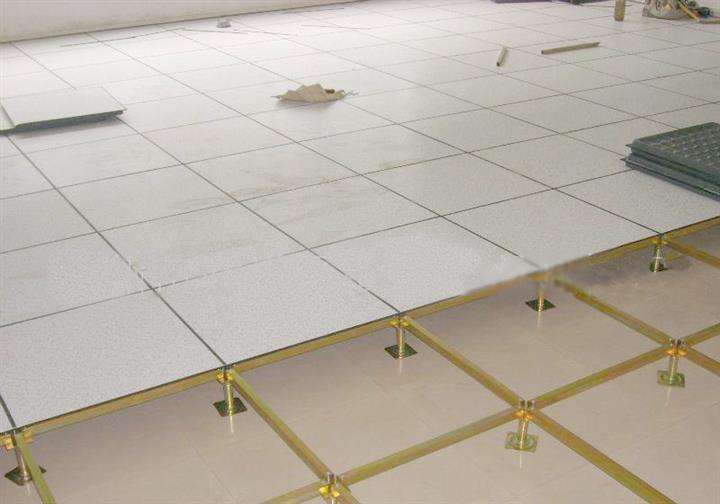

ESD raised flooring

(1) Clean the ground: the original base course ground shall be flat without obvious unevenness. Remove the sundries on the ground with a shovel and clean it.

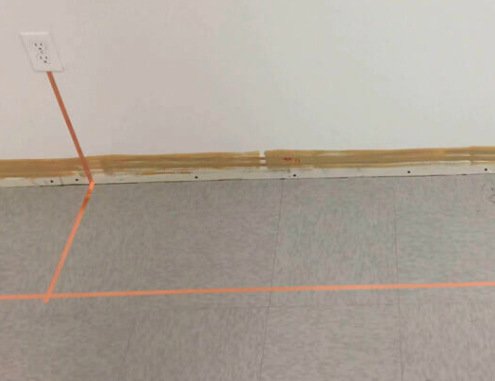

(2) Positioning and setting out: according to the flat size of the room and equipment layout, the laying scheme and reasonable laying method shall be formulated according to the module of the movable floor plate.

Based on the above, after the laying method is determined, centering, square setting, grid division, positioning and setting out shall be carried out, that is, the grid division line shall be marked on the ground, and the elevation line shall be marked on the surrounding walls, so as to facilitate operation control during construction.

(3) Installation and fixation of adjustable supports and beams: the adjustable supports shall be placed according to the elevation control lines snapped on the walls around the room and the division positions snapped on the base floor, the beams shall be erected, and the support height shall be adjusted to the same height of the whole room with a small line and a level ruler. Each nut of the floor support shall be tightened after leveling to form a networked support.

(4) Laying of raised flooring: lay the raised floor plate and adjust the horizontal height to ensure that the four corners are flat and tight. If the raised floor block does not meet the modulus, the insufficient part can be cut and patched according to the actual size (fine when cutting the floor), and equipped with corresponding adjustable supports and cross beams.

(5) Anti static grounding: the raised flooring shall be grounded after installation, and its technical performance shall meet the design requirements and construction acceptance specifications.

ESD Epoxy flooring

- Base surface treatment

- B apply sealing primer

- C lay copper wire, cut groove

- D scrape conductive intermediate paint

ESD Vinyl flooring direct installation ( Both ESD vinyl sheet and ESD vinyl tile)

- Foundation surface (ground) treatment;

- Self leveling cement leveling;

- Apply conductive adhesive

- Lay copper strip into a mesh arrangement;

- ESD vinyl flooring installation

- Welding

- Leveling of plastic welding joint;

- Surface cleaning;

8) Material classification

All steel

- All steel borderless ESD flooring

- All steel ESD flooring of dust-free room

- Protective borderless ESD flooring

- Ceramic ESD flooring metal composite raised floor

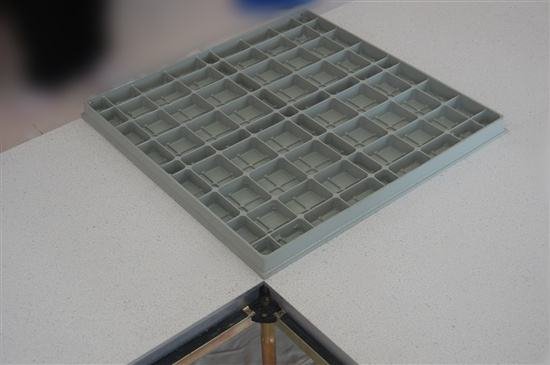

- All steel ESD flooring with ventilation board

Aluminum alloy

- Aluminum alloy ESD flooring with ventilation plate

- Aluminum alloy grid plate

- Aluminum alloy blind plate

Laminated material

- Reinforced composite ESD flooring

- ESD ceramic steel composite raised flooring

Calcium sulfate

Calcium sulfate ESD flooring

ESD vinyl flooring

- Direct laid permanent ESD vinyl flooring

- Permanent ESD vinyl flooring

OA network flooring

All steel OA network flooring

9) Flooring Selection method

- First of all, the total area (or number of pieces) of ESD flooring required for the construction of computer room and the quantity of various accessories (standard support ratio 1:3.5, standard beam ratio 1:5.2) shall be accurately, and allowance shall be reserved to avoid waste or shortage.

- Fully understand the variety and quality of ESD flooring produced by manufacturers, as well as various technical performance indicators. The technical performance of ESD flooring mainly refers to its mechanical and electrical properties. Mechanical properties mainly consider its bearing capacity and wear resistance.

- The load of the anti-static floor shall be determined based on the weight of the heaviest equipment in all equipment in the machine room, so as to prevent permanent deformation or damage of the floor caused by excessive weight of some equipment.

- The ESD flooring changes little under the influence of external environmental conditions. That is, there will be no obvious expansion due to too high or too low external ambient temperature, that is, when the temperature of the machine room is slightly higher, the ESD flooring will expand and cannot be removed and replaced; When the temperature is low, the ESD flooring shrinks, resulting in looseness. The shrinkage of the ESD flooring affected by the environment shall be less than 0.5mm, and the deflection of the board surface shall be less than 0.25mm.

- The surface of the ESD flooring shall be non reflective, non slippery, corrosion-resistant, non dusting, non dust absorption and easy to clean.

10) Installation requirements

(1) The floor shall be laid after the completion of indoor civil engineering and decoration;

(2) The floor shall be flat, clean, dry, free of sundries and dust;

(3) Cables, electrical appliances, air pipes and air conditioning systems arranged under the floor shall be completed before installing the floor;

(4) The fixing of heavy equipment base shall be completed, the equipment shall be installed on the base, and the height of the base shall be consistent with the finished height of the upper surface of the floor;

(5) Power supply and water source are available at the construction site.

11) Installation acceptance criteria

(1) The underside and surface of the raised floor shall be clean and free of dust and relics;

(2) The floor surface shall be free of scratch, coating falling off and edge strip damage;

(3) After paving, the floor shall be stable and firm as a whole, and personnel shall walk on it without shaking or sound;

(4) The edge strip of the floor shall be in a straight line, and the dislocation of adjacent floors shall not be greater than 1mm;

(5) The height difference between adjacent ground plates shall not be greater than 1mm.

12) Quality identification

Good ESD flooring should be environmentally friendly. Adhesives should be used in the production process of ESD flooring substrate, and formaldehyde is one of the main components of adhesives. Therefore, ESD flooring often contains formaldehyde, which is known as “invisible killer”. The formaldehyde emission of the substrate shall meet the safety standard, that is, the formaldehyde emission shall be less than 9mg / 100g. The substrate below this standard is harmless to human body. When buying ESD flooring, if you smell a pungent smell, don’t buy it. The ESD flooring should be moisture-proof. The moisture-proof performance should be reflected by the index of water absorption thickness expansion rate. The higher the index value, the worse the moisture-proof performance. The floor with poor moisture-proof performance is very likely to have problems such as expansion and deformation in the humid environment in spring and rainy season. We remind consumers to buy floors with a water absorption thickness expansion rate of less than 10%..

Good ESD flooring does not fade

Some imitation solid wood floors look bright in color and delicate in pattern. However, the designs and colors of some imitation solid wood floors, such as chalk words on the blackboard, will be completely lost when wiped with an eraser. When consumers buy floors, they must choose products with light fastness of more than Grade 7, otherwise, your shoes will become “embroidered shoes”.

The ESD flooring shall be wear-resistant

High wear resistance is one of the most outstanding advantages of laminate flooring. The mainstream products in the world laminate market should reach T or P wear resistance. Many low-cost floors in the market use low-quality wear-resistant paper to reduce the cost, its wear resistance is naturally low, and the service life will be greatly shortened.

13) Flooring installation

Requirements for laying site

- The floor shall be laid after the completion of indoor civil engineering and decoration construction;

- The ground shall be flat, dry, free of sundries and dust;

- The available space under the floor, layout and laying of cables, circuits, waterways, air and other pipelines and air conditioning system shall be completed before the installation of the floor;

- The fixing of large heavy equipment base shall be completed, the equipment shall be installed on the base, and the base height shall be consistent with the finished height of the upper surface of the floor;

- Power supply and water source are available at the construction site.

Floor installation and laying tools

- Marble cutting saw, pistol drill, hammer, hand grinder;

- Laser level measuring instrument, network laser scanner;

- Bubble level, tape measure and ink line;

- Plate aspirator, nut adjusting wrench, cross screwdriver;

- Vacuum cleaner, broom, mop;

Installation steps

- Carefully check the flatness of the ground and the verticality of the wall. In case of major defects or local reconstruction, it shall be proposed to the relevant departments.

- Draw the horizontal line, and snap the floor installation height onto the wall with ink line to ensure that the laid floor is at the same level. Measure the indoor length, width and select the reference position, and snap the network grid line of the installation support on the ground to ensure that the laying is neat and beautiful, and reduce the cutting of the floor as much as possible;

- Adjust the support to be installed to the same required height and place the support to the cross intersection of the ground grid line;

- Fix the truss beam to the support with installation screws, and calibrate the truss beam one by one with level ruler and square ruler to make it both in the same plane and perpendicular to each other;

- Place the raised floor on the assembled truss with the suction plate device;

- If the remaining size near the wall is less than the length of the raised floor, it can be patched by cutting the floor;

- When laying the floor, level it block by block with a bubble level. The height of the raised floor is adjusted by the adjustable support. Handle it gently during the laying process to prevent scratching the floor and damaging the edge strip. At the same time, clean it while laying to avoid leaving sundries and dust under the floor;

- When heavy equipment is set in the machine room, a support can be installed under the floor of the equipment base to prevent floor deformation;

- When HPL decorative board needs cutting or opening processing, its opening concave corner shall prevent the processed floor decorative surface from cracking.

14) Some of the world famouns brand of ESD flooring

This article is written by Longda Flooring (www.longdaflooring.com), a leading vinyl sheet flooring manufacturer from China.

Please contact Longda flooring for a free quote on your vinyl flooring needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longda flooring

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086-138 2882 1440

- Fax: 86-312-5863390

- Email: sales@longdaflooring.com

Follow us

Copy right by Longda China