Difference Between Vinyl Flooring and Rubber Flooring

Vinyl flooring and rubber flooring belong to resilient flooring and are widely used in building materials industry, but many people often can’t distinguish their specific differences. Today, let’s talk about how to correctly distinguish vinyl flooring and rubber flooring.

What is vinyl flooring?

Vinyl flooring refers to the flooring produced with PVC materials. Specifically, it is produced by taking polyvinyl chloride and its copolymer resin as the main raw material, adding fillers, plasticizers, stabilizers, colorants and other auxiliary materials on sheet continuous substrate through coating process or calendering, extrusion or extrusion process

Also known as “light floor material”, it is a very popular new type of light flooring decoration material in the world and widely used, such as houses, hospitals, schools, office buildings, factories, public places, supermarkets, businesses, etc.

Other name: PVC flooring, homogeneous & heterogeneous vinyl flooring.

What is rubber flooring?

Rubber flooring is made of natural rubber, synthetic rubber and other polymer materials. Styrene butadiene, high benzene and cis-1,4-polybutadiene rubber are synthetic rubber, which are by-products of petroleum. Natural rubber refers to the rubber harvested from artificially cultivated rubber trees.

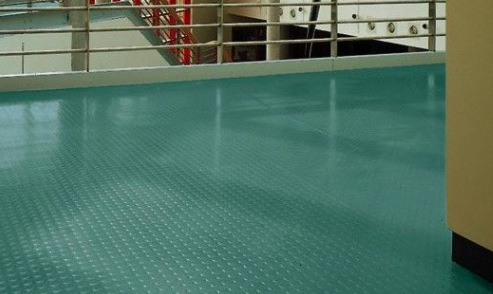

For it’s excellent performance in wear resistance, the rubber flooring is widely use in public transport tools such as plane, train and ship.

Below we will explain in details what are the dfferences between vinyl flooring and rubber flooring.

It’s an in-depth article that takes 20 minutes to read.

Navigation, click to jump to the section you want to read

Difference Between Vinyl Flooring and Rubber Flooring

1) Difference in materials:

Vinyl flooring refers to the flooring produced with PVC materials. Specifically, it is produced by taking polyvinyl chloride and its copolymer resin as the main raw material, adding fillers, plasticizers, stabilizers, colorants and other auxiliary materials on sheet continuous substrate through coating process or calendering, extrusion or extrusion process

Rubber flooring is a flooring made of natural rubber, synthetic rubber and other polymer materials. Styrene butadiene, high benzene and cis-1,4-polybutadiene rubber are synthetic rubber, which are by-products of petroleum. Natural rubber refers to the rubber harvested from artificially cultivated rubber trees.

2) Difference in flooring structure:

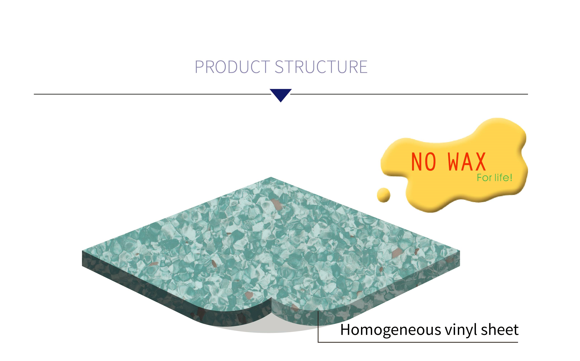

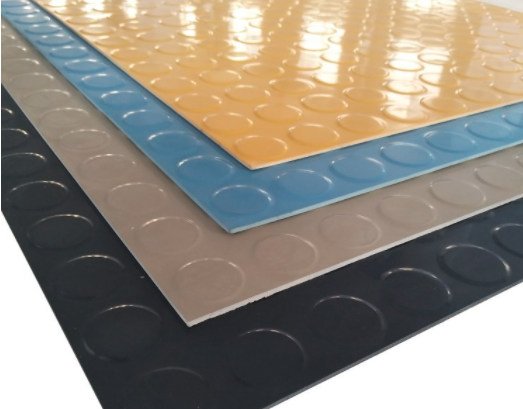

Both vinyl flooring and rubber flooring are the same in homogeneous flooring. Homogeneous means that it is the same design and color from top to bottom.

But difference in heterogeneous flooring.

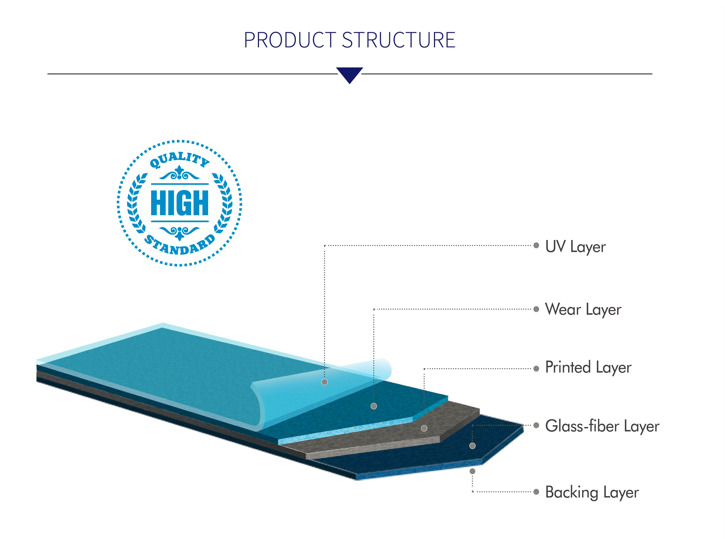

For vinyl flooring, heterogeneous means that it has multi-layer structure, which is generally formed by laminating 4 ~ 5 layers of structure, generally including wear-resistant layer (including UV treatment), printing film layer, glass fiber layer, elastic foaming layer, base layer, etc.

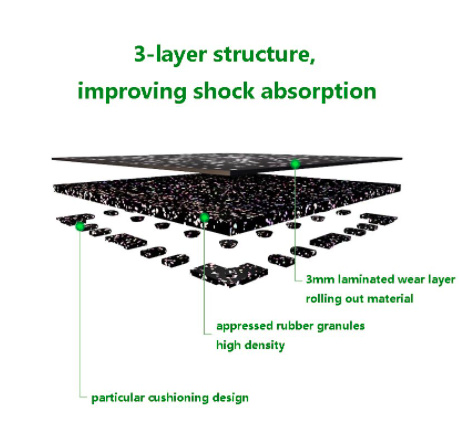

For Rubber flooring, heterogeneous refers to that the floor is based on natural rubber or synthetic rubber, and the structure includes a wear-resistant layer and other compacted layers with different composition and / or design, and the compacted layer includes a skeleton layer.

3) Difference in colors:

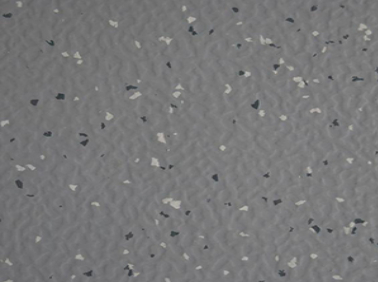

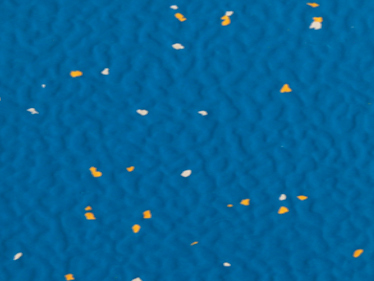

There are many designs and colors of vinyl flooring, which can be combined arbitrarily, and give designers more choices. Homogeneous flooring can be very beautiful, but heterogeneous is even better, it will make printing plates for all the patterns and then print it on the flooring, which will be 100% vivid and looks very beautiful.

The coloring of rubber floor is difficult, because rubber has strong color absorption, so the color of most rubber floors is relatively single

4) Difference in installation:

Vinyl flooring has light texture and convenient and fast installation;

The rubber flooring is heavy and difficult to install. Moreover, the installation method of rubber flooring is more complicated. If the method is wrong, bubbles will appear, and the requirements for self leveling foundation are more perfect. Otherwise, the defects of base course will be exaggerated.

5) Difference in wear resistance:

Both are performing very well in wear resistance, and can reach level T, but rubber flooring might can have a little bit better in wear resistance.

6) Difference in Cost:

Vinyl flooring is with much lower cost.

Rubber flooring is with much higher cost. 2-3 times than vinyl flooring.

7) Difference in Application

Basically both can apply to the same places.

But since there is huge difference in cost, vinyl flooring is taking 95% of market share.

For Vinyl flooring: In terms of places of usage, it is divided into residential flooring and commercial flooring.

Residential flooring can be used in living room, bedroom, kitchen, balcony, children room, bathroom, etc

Commercial flooring can be used in below:

Education (including schools, training centers, kindergartens, etc.)

Medical (including hospitals, laboratories, pharmaceutical factories, nursing homes, etc.)

Commercial (including shopping malls, supermarkets, hotels, entertainment and leisure centers, catering industry, specialty stores, etc.)

Sports (stadiums, activity centers, etc.)

Office (office building, conference room, etc.)

Industrial (factory building, warehouse, etc.)

Transportation (airport, railway station, bus station, wharf, etc.)

Rubber flooring is mainly use in public transport tools such as plane, train and ship.

Conclusion: vinyl flooring and rubber flooring will have more or less the same function and quality, but since the cost of rubber flooring is much higher, so vinyl flooring is the better choice in 95% of the cases.

Introduction of Longda Vinyl flooring.

Longda Flooring is the leading vinyl sheet flooring manufacturer from China. We have more than 300+ stylish patterns and increasing every month.

The annual capacity is 36 million m² . And our 6 million m² daily stock can support next day shipping.

We have 4 main products:

ESD Vinyl Sheet

Heterogeneous Vinyl Sheet

Homogeneous Vinyl Sheet

Wall Covering

This article is written by Longda Flooring (www.longdaflooring.com), a leading vinyl sheet flooring manufacturer from China.

Please contact Longda flooring for a free quote on your vinyl flooring needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longda flooring

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086-138 2882 1440

- Fax: 86-312-5863390

- Email: sales@longdaflooring.com

Follow us

Copy right by Longda China