6 Factors to Determine the Vinyl Flooring Cost

Vinyl flooring is becoming the most popular flooring materials today. It is eco-friendly 100% recyclable. It is durable, waterproof, fireproof, slip resistant, antibacterial and comfort to walk. We can foresee the rapid growth each year.

There are many comprehensive factors affecting the cost of vinyl flooring.

Today we will list 6 key factors of determine the vinyl flooring cost.

It is an in-depth article which takes 15 minutes to read.

Navigation, click to jump to the section you want to read

6 Factors to Determine the Vinyl Flooring Cost

1. PVC content percentage

The main raw material of vinyl floor is PVC. Its price is more than ten times that of calcium powder. The proportion of PVC and calcium powder ingredients determines the price of vinyl floors. Calcium powder accounts for a large proportion, so the price is naturally cheap. The proportion of PVC is large, and the price is naturally expensive, which also determines the abrasion resistance of PVC floors. The higher the PVC content, the more abrasion resistance.

2. New materials or Recycled materials

Good PVC floor is made of new materials, and some are made of recycled materials, so there is a clear difference in price. The PVC plastic floor made of recycled materials tastes pungent and harmful to human body.

3. Different vinyl flooring types

For vinyl sheet: ESD vinyl flooring is the one of the most expensive flooring cause it add the anti-static function. Sports vinyl flooring is also expensive cause normally it is thicker. Homogeneous vinyl flooring is more expensive than heterogeneous vinyl flooring sheet. And commercial grade vinyl sheet flooring is higher cost than residential grade sheet vinyl. And the sponge PVC flooring vinyl sheet for residential is the lowest price.

For LVP: SPC is more expensive than LVT. And LVT can make some of the lowest cost version with very thin thickness.

4. Thickness and wear-resistant layer of PVC plastic floor.

The conventional thickness of vinyl floor is 1.6mm to 8mm. The thicker the total thickness of the same type of PVC floor, the more raw materials will be used, so it is more expensive. The 6mm PVC plastic floor of the same type, which is more expensive than the 5mm PVC plastic floor.

If the thickness is the same, the price is different, that is to say, the wear-resistant layer thickness of PVC floor is different. The thickness of the wear-resistant layer also determines the service life of the floor. The higher the thickness of the wear-resistant layer, the better the material. The more difficult the technology is, the higher the cost is, and the higher the price is naturally.

5. Production process.

Most domestic factories use calendering hot paste technology, which has higher forming efficiency, and the adhesion fastness of PVC floor is also higher. Some factories use scraping method. Two different processes require different production equipment, labor and financial cost investment are also different, which will also lead to the difference in the price of PVC floor.

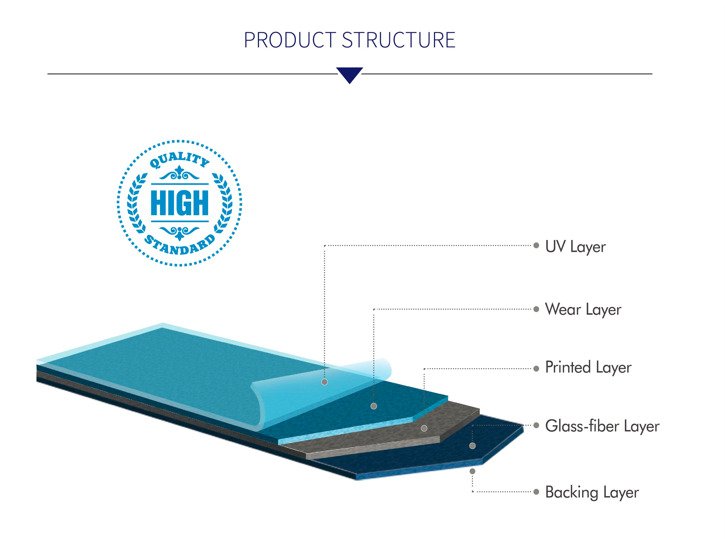

6. With or Without UV coating

Whether the PVC plastic floor has a UV layer. The surface of the PVC plastic floor treated by the UV layer will be brighter and easier to clean and maintain.

Better choice: Vinyl Flooring Manufacturers from Mainland China

If you are buying a big quantity, or you need vinyl flooring for commercial projects; you can also buy the vinyl flooring from mainland China.

As most of the companies are import vinyl flooring from China, you can save cost if you are buying directly from China.

Top 10 Vinyl Flooring Manufacturers in China

Among which, Longda flooring is the largest vinyl sheet flooring manufacturer from China.

Main products included:

Homogeneous vinyl sheet flooring

Heterogeneous vinyl sheet flooring

Woven vinyl flooring

SPC, LVT, LVP,

It is the perfect suppliers for your commercial flooring needs such as: school, hospital, healthcare, lab, library, transportation stations, workshop, clean room etc.

FOR MORE INFORMATION ON OUR VINYL FLOORING, PLEASE CONTACT OUR TEAM TODAY.